Using Terminal Blocks and Connectors to Simplify Industrial Wiring: A Beginner's Guide

Industrial wiring is very complex. It involves plenty of cables and connections that can easily get out of hand and become unmanageable if you don’t approach the job systematically. It is essential to make sure the wiring systems are efficient and reliable, to ensure both the performance of the industrial operations and safety. This is where terminal blocks and connectors come into play. Being essential tools for anyone involved in industrial electrical work, they offer an ideal solution for organizing and simplifying wiring tasks. This article will explore the different uses of terminal blocks and connectors, and provide practical tips for their implementation in industrial settings.

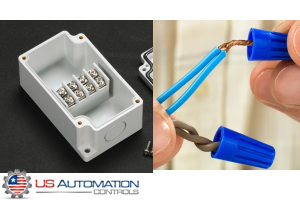

What Are Terminal Blocks and Connectors?

Terminal blocks are modular, insulated devices used for connecting multiple wires. They allow for the electrical power and signals to be distributed in an organized way. They come in different types:

- Screw terminals that use screws to clamp the wires.

- Spring-clamp terminals that use spring pressure to hold the wires.

- Push-in terminals which allow wires to be inserted and held in place without tools.

On the other hand, connectors are used to join sections of circuits together. Connectors come in several types as well:

- Plug-in connectors in which the connection is quick and detachable.

- Screw connectors that secure wires in place using screws

- Crimp connectors which are attached to wires by crimping.

Benefits of Using Terminal Blocks and Connectors

There are several ways in which terminal blocks and connectors improve industrial wiring systems. Here is a look into three of their benefits:

Safety Enhancement

Using terminal blocks and connectors can provide secure and reliable connections. This reduces the risk of electrical faults and short circuits. With safety being a crucial factor when it comes to industrial electrical work, it is a wise choice to use terminal blocks and connectors.

Improved Organization

Terminal blocks and connectors also improve the organization of a wiring system and make troubleshooting much easier. They delineate different circuits and make connections accessible.

An organized setup can be a game changer when it comes to maintenance and repair. It can reduce downtime by making the wiring system far more understandable, and the connections more accessible.

Flexibility

These essential components make a wiring system more flexible and scalable. Modifications and expansions are much more easily done when a wiring system is set up using terminal blocks and connectors. This is particularly useful when the industrial environment is very dynamic and the requirements can change frequently.

Common Uses in Industrial Wiring

Being versatile components, terminal blocks, and connectors allow for a wide range of industrial applications. In control panels and switchgear, they offer an organized way to manage the many connections that an operation necessitates. Another group of systems that significantly benefit from the structured wiring that terminal blocks and connectors provide are industrial automation systems. They involve a set of sensors, actuators, and controllers with complex wiring. These components can ensure a safe and efficient routing of electrical power to different parts of a facility in power distribution systems. The clarity and reliability of connections in signal wiring also rely greatly on terminal blocks and connectors.

Installing Terminal Blocks and Connectors: A Step-by-Step Guide

Preparing the essential tools and taking safety measures is a necessity when installing terminal blocks and connectors. Here is a step-by-step guide:

Tools and Materials

To install these components, you will need:

- Screwdrivers

- Wire strippers

- Crimping tools (for crimp connectors)

- Labeling materials

- Terminal blocks and connectors

Safety Precautions

Pay attention to these safety tips:

- Disconnect power before you start working (this applies to any wiring work).

- Use insulated tools to prevent accidents.

Installation Process for Terminal Blocks

- Mount the terminal blocks on a DIN rail or panel.

- Strip the insulation from the ends of the wires.

- Insert the stripped wire into the terminal block.

- Tighten the screw or activate the spring clamp to secure the wire.

Installation Process for Connectors

- Prepare the wires by stripping the insulation.

- For crimp connectors, insert the wire into the connector and use a crimping tool to secure it (for plug-in connectors, simply plug the wire into the corresponding slot).

- Ensure all connections are secure and properly insulated.

Best Practices for Using Terminal Blocks and Connectors

Here are some tips to follow if you want to get the most out of terminal blocks and connectors:

- Properly label and document all connections so they are easily identified later. This helps make the process of troubleshooting and modifications far easier in the future.

- Inspect connections regularly to make sure they stay secure and in good condition.

- Use high-quality components to avoid reliability issues. Make sure you choose a good and responsible supplier.

By following the above tips and sticking to those practices, you can ensure an efficient wiring system with a long lifespan.

Troubleshooting and Maintenance Tips

Loose connections, corrosion, and insulation damage are common issues with terminal blocks and connectors. Regularly inspect all connections and look for signs of wear and tear. While you do so, tighten any loose screws and replace damaged components. Ensure that all connections are properly insulated and consider using corrosion-resistant materials to prevent corrosion.

Automation Controls Distributors and Wholesalers Based in Short Hills, NJ

US Automation Controls is the best distributor for all the supplies you need in industrial electrical work. We offer a very wide range of automation controls, including but not limited to terminal blocks and connectors. With more than 50 years of experience, we understand the requirements of your wiring work very well and are here to fulfill them. Founded by one of the design engineers of AGASTAT relays, US Automation Controls has its roots deep in a fundamental understanding of an industrial electrician’s work. Contact us today to receive quality terminal blocks, connectors, and more industrial automation controls for a good price!

Terminal Blocks and Connectors Installation FAQ

What are the main types of terminal blocks?

There are several types, including screw terminal blocks (requiring a screwdriver), spring terminal blocks (tool-less), and push-in terminal blocks (quick and easy insertion). The choice depends on factors like wire size, frequency of connection, and environment.

How do I choose the right terminal block for my application?

Consider factors such as wire gauge, current and voltage ratings, number of poles, mounting type, and environmental conditions. Also, ensure compatibility with other components in your system.

What are the benefits of using connectors in industrial wiring?

Connectors offer flexibility, modularity, and ease of assembly. They allow for quick disconnections, making troubleshooting and maintenance easier. Additionally, they can help reduce wiring errors.

Can I use terminal blocks and connectors interchangeably?

While both serve to connect wires, they have different purposes. Terminal blocks are typically used for permanent or semi-permanent connections, while connectors are more suitable for frequent disconnections.

How do I ensure a secure connection with terminal blocks?

Follow the manufacturer's instructions carefully. Tighten screws or lever mechanisms properly. For push-in terminal blocks, ensure the wire is fully inserted. Regular inspection can also help identify loose connections.